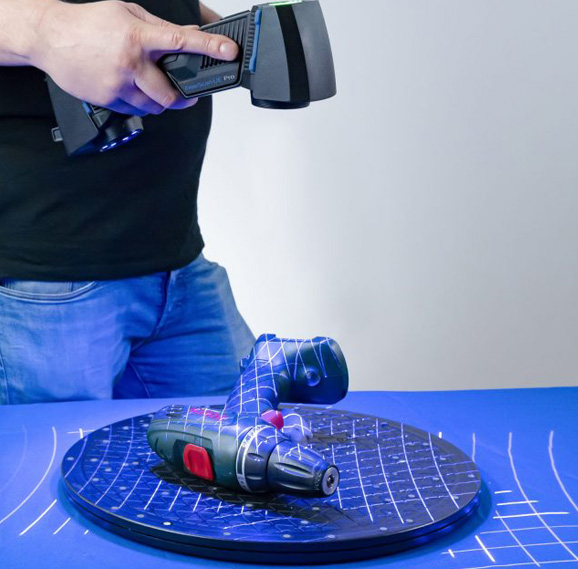

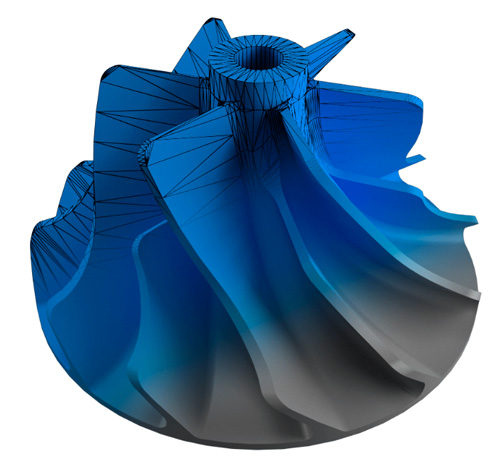

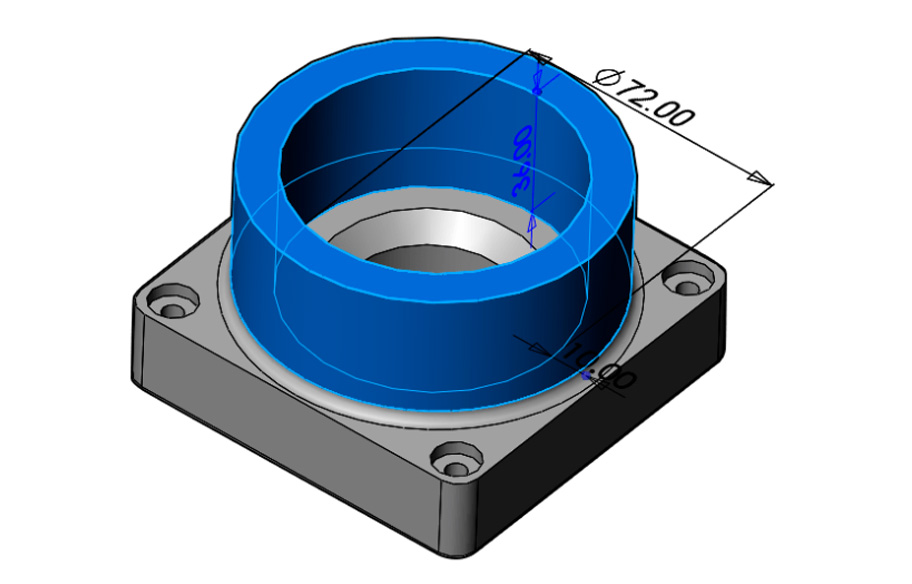

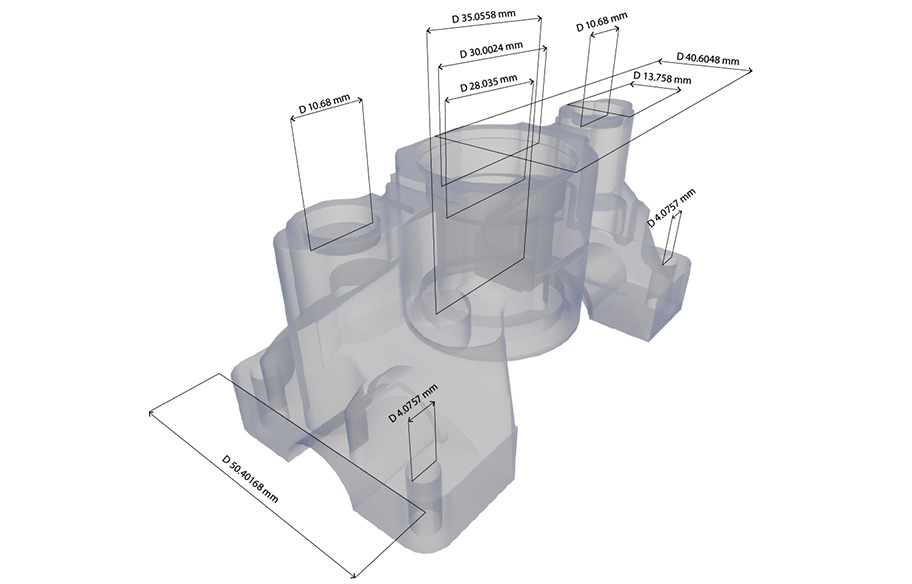

Are you looking to digitize products, parts, or components into workable 3D CAD data? Do you want to digitize your products and parts so that you can then modernize your product and manufacturing development processes and remove the requirement for a physical inventory? If so, you can benefit significantly from our reverse engineering expertise. Flatworld Solutions is a leading reverse engineering services company that can help you get detailed 3D models of any product or equipment components so that you can utilize them to quickly build the best possible product. We also leverage the latest technologies to deliver top quality services to our clients.