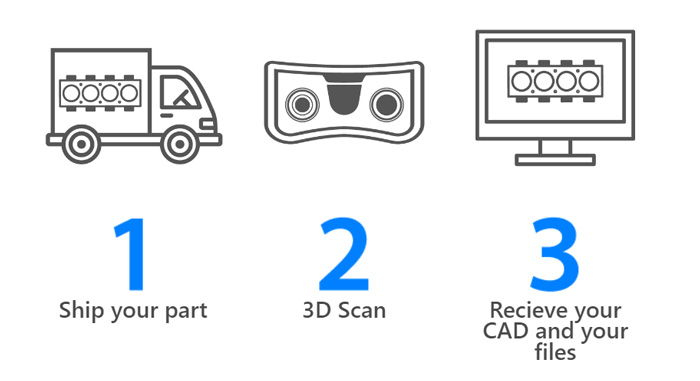

If you are looking for a company that offers exceptional 3D scanning services, you are in the right place. We acquire 3D measurement data from all kinds of objects, and then we convert them into usable data for inspection, 3D printing, or reverse-engineering.

The CAP-CP Platform Provide Gom (Optical 3D Scanner), Free Scan Combo 3D scanning services in India. It uses structured blue light high-end 3D scanning technology that provides highly accurate 3D Scans with detailed resolution at high speed. With this, we provide repeatable, accurate measurements with flexibility and process reliability.

We are Provide the allover India 3D scanning service for onsite or can also be done in-house, depending on your needs.